As a large company, we are responsible for the various ways we create an impact across society, in the Benelux and beyond. Alongside the execution of our strategy, we also need to look at the value we create over the longer term and on a broader range of societal topics. We have based the output and outcomes of our value creation model on our key material topics and linked these to the longer-term impact on the UN's Sustainable development goals (SDGs).

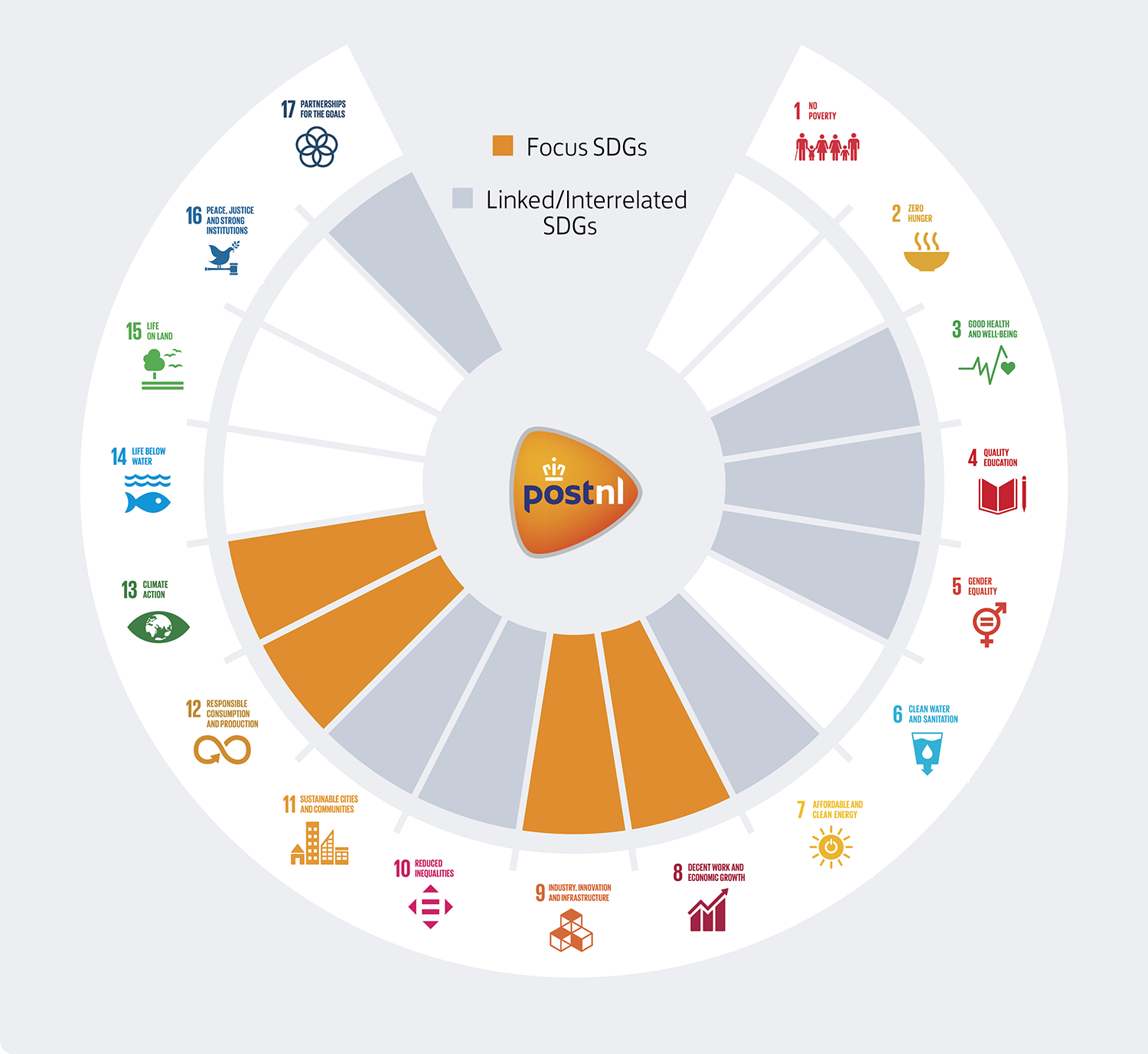

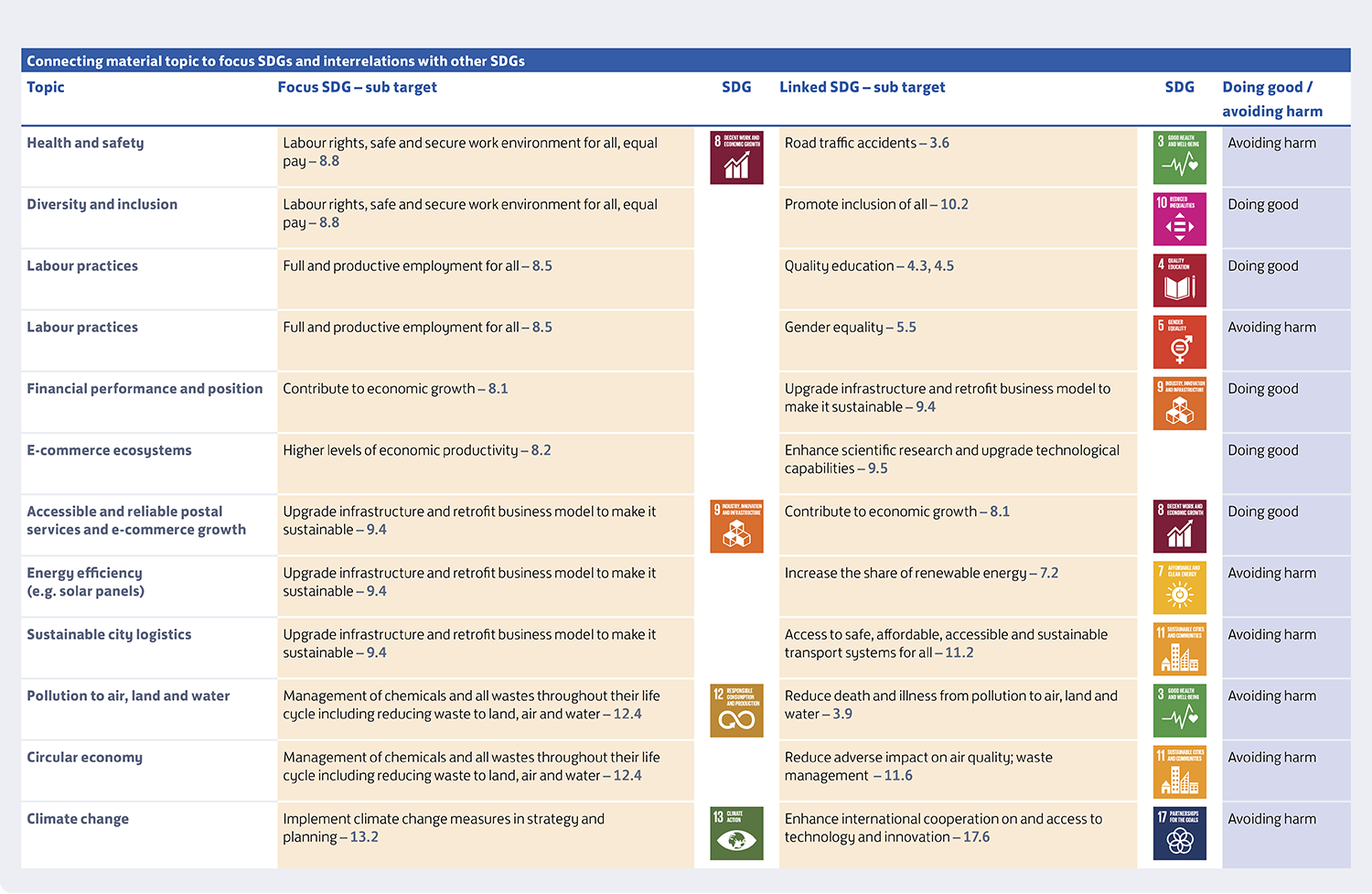

We have identified four focus SDGs that our business activities have the greatest impact on. From our own operations, decent work and economic growth (SDG 8) is our most relevant SDG, followed by climate action (SDG 13). Through collaboration along our value chain, we focus on making progress on industry, innovation and infrastructure (SDG 9) and responsible consumption and production (SDG 12). To progress on sustainable development and improve the impact we have on society, we are focusing on implementing new initiatives. And because all SDGs are interrelated, the actions we take to make headway with our four focus SDGs impact all other SDGs.

We have developed our approach towards our focus SDGs and identified relevant interrelations between other SDGs based on specific SDG sub targets as defined by the United Nations (UN). We have mapped the material topics to the focus SDGs and the contribution they make to the linked SDGs, as seen in the table below.

Following a thorough preparation and testing process, in October we opened an innovative new parcel sorting centre, the SPSC. This state-of-the-art facility enables us to substantially increase our sorting capacity and processing efficiency, and is a prime example of how we are integrating value across all four domains.

Located in Nieuwegein, the Netherlands, the SPSC is a highly robotised parcel sorting centre. It is designed to process parcels up to the size of a large shoe box. This enables us to sort small packages 24/7, delivering customers' parcels even faster and more efficiently than before. Small parcels are a fast-growing part of the e-commerce business, partly due to the need to remove air from parcels. The capacity of the SPSC is equal to five traditional sorting centres and is a significant expansion of the capacity of our network.

Research shows that on average 30% of the content of a package consists of air. In 2021, our fulfilment centre in Houten worked with teams from across the company to implement algorithms designed to optimise packaging, further reducing air and providing customers with better packaging options.

We advise and incentivise customers to use custom-designed boxes to perfectly fit the size of goods. Reducing the amount of air in parcels leads to more efficient transport and helps lower our CO2 emissions. Smaller parcels also means less packaging material which results in less waste.

We have set up two webshops dedicated to packaging, one for PostNL customers and one for other e-tailers.

We are increasingly using data, digitalisation and robotisation to improve our processes, and the SPSC is equipped with an array of innovative tools and technologies that support our people. The centre has 175 robots that transport the parcels internally, while robotic arms lift and bag the parcels. This makes the sorting process easier for depot workers and van loading easier for deliverers.

Processing small parcels separately enables us to create more capacity at our other 26 parcel sorting centres, which helps us further grow e-commerce and operate more efficiently. The SPSC is part of our strong focus on capital allocation. This enables us to grow the business, become more flexible, adapt ourselves to extreme peak volumes and better manage costs, contributing to our financial health.