2.4 Resource use and circular economy

In this section, we provide disclosures on our material impacts, risks, and opportunities relating to resource use and the circular economy. At PostNL, we recognise that responsible resource management is crucial for sustainable growth. This section will elaborate on our focus on addressing resource inflow and outflow waste.

2.4.1 Our strategy

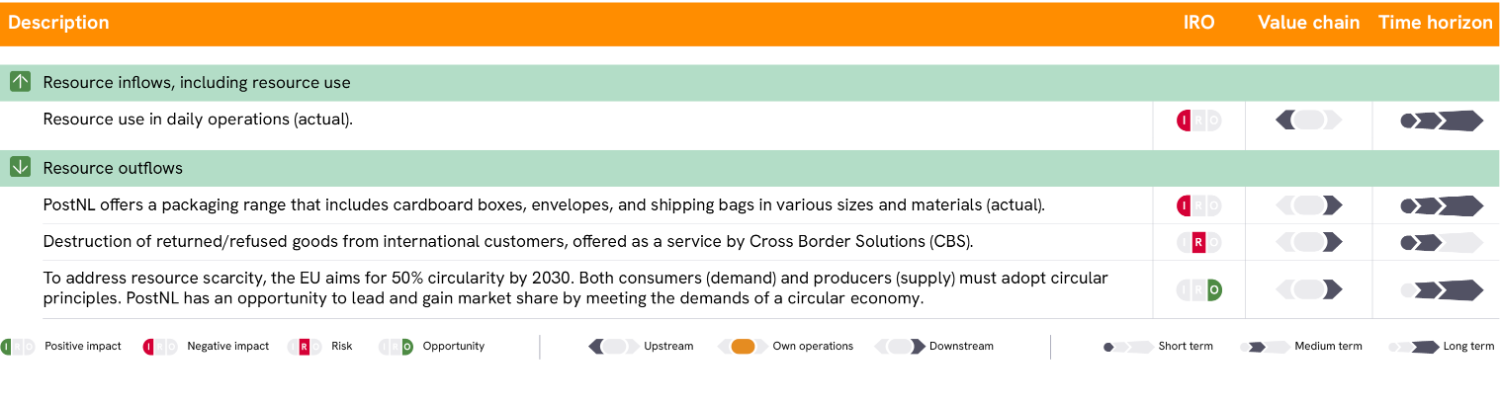

With the support of our Double materiality assessment, we identified the most material sustainability matters, including those related to resource use and the circular economy. For these areas, we assessed potential material impacts, risks, and opportunities across the following topics:

- Resource inflows, including resource use

- Resource outflow, waste from our operations.

For further information on how our material topics connect to our value chain, please refer to Our value chain and material topics section within the General disclosures. More information on how we address these material topics can be found in Our policies and in Our performance later in this Resource use and circular economy section.

2.4.2 Our policies

We believe it is important to handle resources carefully, which is why we want to prevent residual waste and extend the lifespan of the materials we use in our operations. We work with partners on solutions to use as many recycled and reusable materials as possible. In doing so, we reduce our impact on the environment and contribute to a circular economy. The impacts, risks and opportunities related to resource inflows, resource outflows and waste are covered by the environmental policy and the procurement policy.

Stakeholder engagement

Through structured engagements, including our DMA, we validate material topics and gather feedback from stakeholders, including suppliers, customers, and NGOs. Stakeholder input ensures alignment with market expectations and informs our sustainability strategies. These policies are publicly accessible on our website and are communicated to suppliers and business partners where relevant. The revised group policy came into effect in September 2024. As such, no significant improvements are expected for 2025.

Policies overview

PostNL’s environmental and procurement policies support our commitment to circularity, aiming to prevent waste, extend material lifespans, and reduce reliance on virgin resources. Aligned with our science-based targets (SBTs), they focus on resource inflows, outflows, and waste. Our circular purchasing strategy follows the 10R circularity ladder, prioritising recycled and reusable materials while minimising waste and extending product lifespan. We aim for zero residual waste by 2040 through repair, reuse, and recycling. This voluntary target underscores our proactive approach to anticipated future EU circular economy regulations. Our procurement policy is aligned with our science-based targets (SBTs) by addressing scope 3 emissions from purchased goods, services, and waste, and working closely with suppliers to reduce material impacts. This approach ensures that our procurement decisions contribute to both environmental responsibility and long-term sustainability goals.

Addressing related impacts, risks and opportunities

We actively collaborate with suppliers, customers, and partners to enhance our impact and mitigate risks across our value chain.

- Negative impact (upstream, own operations): We mitigate resource use in our value chain through sustainable procurement initiatives. Suppliers must hold sustainability certifications and provide material data, enabling us to prioritise actions, for example to optimise materials and to trial reusable and recycled solutions, for short-, medium-, and long-term goals.

- Negative impact (downstream): We reduce the environmental impact of packaging by promoting circular business models and scalable re-commerce solutions, supporting sustainability targets across all time horizons.

- Risk (downstream): To prevent unnecessary destruction of returned goods, we collaborate with business customers to develop alternative solutions, focusing on short- and medium-term mitigation.

- Opportunity (upstream, downstream): We drive circularity by expanding circular business models and participating in Circular Shopping 2030, supporting medium- and long-term sustainability goals.

By addressing both risks and opportunities, we strive to reduce environmental impact throughout our entire value chain.

Monitoring

The Procurement & Services department oversees procurement, including waste management and supplier sustainability, with quarterly performance assessments tracked via dashboards to monitor progress. In the Netherlands, it manages procurement directly, while in Belgium, PostNL Belgium collaborates with Dutch counterparts. The Procurement & Services director is authorised by the Board of Management as the procurement policy owner, while the ESG director oversees environmental policies.

2.4.3 Our performance

At PostNL, our vision for circularity involves the elimination of residual waste and the promotion of material reuse, fostering a transition towards a fully circular economy. By 2040, we aspire to achieve net zero waste, ensuring that all materials we handle are processed in a circular manner. This ambition underpins our commitment to reducing reliance on virgin resources by prioritising the use of secondary (recycled) materials, embracing sustainable sourcing practices, and increasing the adoption of renewable resources. For more information on the actions related to climate change mitigation, see Our performance in the Climate change section.

Resource inflows, including resource use

Actions

To realise our goals, we are actively developing comprehensive action plans. We have already made significant progress, and expect to have these plans completed in 2025. Each action will define its scope, timeline and, where relevant, the impacted stakeholder groups. These measures align with our commitment to embedding sustainability across our operations, paving the way for a resilient, circular future.

PostNL’s approach includes:

- Circular product design: While PostNL's operations are not centred on production, we aim to gradually integrate circular principles into our procurement practices. For example, we are exploring the potential use of products designed for durability, repairability, and recyclability, such as reusable pallet boxes and mono-material airmail bags.

- Increase of circular material use rate: PostNL seeks to increase its use of circular materials by engaging suppliers to provide materials with recycled content where feasible. While this is a focus area, the shift toward higher circular material use is incremental and dependent on supplier capabilities and market availability.

- Minimisation of primary raw materials: Our procurement strategy encourages the reduction of virgin material use by requesting transparency from suppliers regarding material composition and prioritising alternatives with a higher proportion of recycled or renewable content. Although progress is being made, this remains a developing area.

- Sustainable sourcing of renewable resources: PostNL is working towards more sustainable sourcing practices by favouring renewable resources that align with cascading principles. While efforts are underway to explore bio-based alternatives and recycled materials, the integration of these resources into our operations is gradual and subject to supplier readiness.

- Waste management: Our waste management improvements focus on enhancing recycling processes, optimising waste separation practices at operational sites, and collaborating with partners to ensure proper treatment of all waste streams. These efforts directly reduce residual waste and improve overall resource efficiency.

- Other circular-economy related topics: PostNL actively promotes circular business models in its downstream operations, such as re-commerce solutions and e-waste collection, contributing to broader circular economy objectives.

PostNL acknowledges that sustainable materials may increase procurement costs, impacting budgets and pricing. However, we remain committed to balancing financial considerations with long-term sustainability goals.

Key actions - sustainable procurement

Supplier requirements

Suppliers are required to provide certifications on sustainability. To evaluate the effectiveness of our broader circularity policies, we measure the percentage of contracted suppliers assessed on sustainability criteria. Progress is tracked via a dedicated dashboard, with a target of achieving 75% of suppliers acceptably assessed by the end of 2025.

Material optimisation

PostNL is tracking resource inflows to be able to report on our resource inflows and transition to materials with lower environmental impact. We prioritised frequently used items essential to logistics and key operational materials with shorter life cycles. By 2025, we aim to report 90% of data from all key material suppliers. For more information, see Metrics later in this section.

Pilot projects

PostNL is testing mono-material airmail bags and expanding reusable pallet box use, with potential for increased recycled content. We replaced plastic A4 labels with laser jet paper, reducing material use despite higher volumes. In 2024, we continued replacing consumables in our international logistics with circular orange pallet boxes, adding 4,000 to bring the total to 9,600. Made from 100% recyclable materials, these boxes last 7–10 years and follow a fully circular, zero-waste process.

Suppliers

Suppliers are critical partners in managing resource inflows. PostNL collaborates with suppliers to align operational requirements with sustainability goals. This includes:

- Company clothing: PostNL has introduced circular uniforms made from 100% sustainable materials, including organic cotton and recycled polyester. Approximately 15% of each uniform consists of fibres from old uniforms.

- Roll containers: New designs reduce material use by replacing wooden bases with recyclable plastic and reducing overall weight by 18.5 kg per unit.

- Reusable label tags: Transitioning from disposable paper tags to laminated, reusable options reduces daily paper consumption.

- Euro-pallets: Customers are encouraged to switch from disposable pallets to reusable Euro-pallets to reduce waste.

By reducing the materials we procure, we aim to achieve a corresponding reduction in CO2 emissions linked to purchased goods (scope 3). More information can be found in the Our policy within this section.

Targets

Our primary target is to achieve a 90% reduction in residual waste by 2040 compared to 2022. This means that no more than 10% of our waste will be unsuitable for reuse, repair, refurbishment, re-manufacturing, repurposing, or recycling. This target is related to our policy objectives. Annually, we set a new target for the upcoming year and will continue to do so up until 2040.

As PostNL is not a production company, our waste comes from material use in our operations, including waste from our office locations. The target scope is therefore related to the use phase of the product life cycle.

Our net-zero waste target for 2040 applies to all PostNL entities. However, the annual reduction percentage currently relates only to our operations in the Netherlands and Belgium, as actual data for other regions is not yet available. This target, while voluntary, anticipates stricter EU regulations related to the circular economy. The target is relative with the base year 2022, excluding GHG removals, carbon credits, or avoided emissions. This target specifically focuses on reducing residual waste by improving waste management practices and enhancing sustainable procurement efforts.

Stakeholder consultations, including business customers, trade organisations, and shareholders, have shaped our targets, ensuring alignment with market and regulatory expectations. The target is formally approved by the director of Procurement & Services under the Board of Management's mandate.

Methodologies and assumptions

We align our waste reduction strategies with the EU Circular Economy Action Plan, which helps guide our efforts to minimise residual waste, increase recycling rates, and transition to a more circular economy. Our targets are based on internal data from waste audits and operational processes, allowing us to track the effectiveness of our waste reduction measures throughout our supply chain. We assume continued regulatory and technological advancements that will enable better recycling infrastructure and material recovery systems over the coming years, helping us meet our long-term target. We also consider local waste management capabilities and infrastructure in the regions we operate by working together with our waste management partner.

Monitoring

Each quarter, we assess performance and determine whether adjustments are required to enhance processes or employee behaviours. Utilising the dashboard provided by our waste management partner, we carefully monitor outcomes. These insights also support tracking progress against our GHG emission reduction targets within the waste category.

Metrics

Resource inflows, including resource use

PostNL relies on essential materials like roll containers, pallets, elastic bands, cardboard, and plastic packaging to ensure secure transport and delivery. However, their frequent use poses environmental challenges, particularly in resource consumption and waste. Packaging materials, such as cardboard and plastic, highlight the need for sustainable practices.

Scope

To determine the scope of materials, we focused mainly on their environmental impact, whilst also including their weight, relevance to our operations, lifecycle, and potential risks. The selected materials are derived from our upstream value chain and in use in our own operations.

Material categories

PostNL’s key resource inflows include:

- Packaging materials: Cardboard and plastic for secure transport in primary and internal logistics.

- Elastic bands, straps, and label tags: Regularly replenished for bundling mail and securing containers

- Plastic wrap: Essential for securing parcels in roll containers during transport.

- Inner and airmail bags: Used for bike deliveries and international shipments, these require frequent replacement.

- Stamps: Essential to postal services, with continuous usage.

- PU gloves and pallets: Gloves protect staff, while pallets support storage and transport.

Materials excluded

Longer-lasting items, such as roll containers, postal crates, and bicycles, are excluded from this year’s reporting due to their durability and lower replacement rates. As this is our first reporting year on this topic, we conducted a baseline study on frequently replenished short-cycle materials to assess scope and supplier data quality. These materials are assumed to have a greater environmental impact due to frequent use, an assumption we will refine through further analysis.

Future reports will aim to expand their scope to include longer-lasting items. While PostNL does not rely on critical raw materials, rare earth elements, or significant water consumption, we continue to monitor their impact for future reporting. In line with EU regulations, including the Single-Use Plastics and Packaging Waste Directives, we are committed to enhancing resource traceability, reducing virgin material use, and adopting circular practices through more sustainable sourcing.

Environmental impact of materials

The materials used in PostNL’s operations—paper/cardboard, plastic, rubber, and wood—have notable environmental impacts:

- Paper/cardboard: High water and energy use; recycling limited by fibre degradation; unsustainable sourcing may contribute to deforestation (source: FSC and Environmental Paper Network).

- Plastic: Fossil fuel-based with high GHG emissions; low recyclability, especially for flexible plastics (source: European Environment Agency).

- Rubber: Natural rubber linked to deforestation; synthetic rubber is energy-intensive and petrochemical-dependent (source: International Rubber Study Group).

- Wood: Renewable, but unsustainable harvesting contributes to habitat loss and carbon emissions; recycling reduces environmental impact but requires processing (source: FAO and UNEP).

PostNL focuses on reducing these impacts by using recycled and sustainably certified materials. For example, 85% of all biological materials used in the reporting period were sustainably sourced, certified by schemes such as FSC (Forest Stewardship Council). We also apply the cascading principle where relevant, ensuring materials like cardboard are reused multiple times before disposal.

Reputational impact

PostNL recognises that materials like elastic bands and cardboard boxes are highly visible and may be perceived as environmental concerns. While these items are not exclusively linked to PostNL, public perception influences our reputation as a sustainable operator. To address this, we have reduced the size of elastic bands to minimise waste, with internal guidelines promoting responsible use and disposal; for cardboard packaging, we prioritise recycled and sustainably sourced materials, certified by schemes like FSC. We remain committed to transparency in resource management and stakeholder engagement to reinforce its sustainability efforts.

Data collection

In 2024, PostNL conducted a pilot study to quantify resource inflows, covering 100% of reported material categories, over the period July 2023 until June 2024. Materials were classified as biological (e.g., cardboard) or technical (e.g., plastic), with weight data collected for new and recycled inputs. The pilot covered 11 key logistical and operational categories: Pallet boxes, cardboard sheets, packaging; label cards, labels, linerless labels; stamps, collector market folders; plastic wraps, tape; disposable gloves; airmail bags, inner delivery bags; cable ties (bag closures); bundle elastic bands.

Assumptions, limitations and goals

- Data completeness: The scope of the pilot was limited to selected products and supplier responses applicable to our locations in The Netherlands, with a supplier response rate of 81%. Where weight data was missing, established methodologies were used to scale figures, to provide a comprehensive view. Refer to the Data extrapolation sustainability statement in the Appendices for information regarding extrapolation of lacking or missing data.

- Challenges: Limited weight data for certain materials highlighted the need for improved supplier engagement and alignment.

- Integration: The findings have been integrated into this year’s reporting, representing a step toward more complete data coverage.

Building on the pilot, PostNL will address data gaps and enhance system integration in the coming years. Planned actions include:

- Expand the scope of waste data collection to include Belgium by 2025.

- Strengthening collaboration with suppliers to improve data quality and availability.

- Aligning procurement systems with sustainability reporting needs to enable real-time tracking.

- Expanding the scope of reporting to include critical raw materials, rare earths, and long-cycle materials like roll containers and postal crates.

PostNL Resource inflows as indicated

2023 - 2024

| Year ended at 31 December | 2023 | 2024 |

|---|---|---|

| Total amount of technical materials (tonnes) | not reported | 270 |

| Total amount of biological materials (tonnes) | not reported | 3,445 |

| Total weight of technical and biological products (tonnes) | not reported | 3,715 |

| Share of sustainably sourced biological materials with a certification (%) | not reported | 45% |

| Weight in absolute value of recycled components (tonnes) | not reported | 2,704 |

| Recylced components as share of total amount of weight of products (%) | not reported | 73% |

Starting in 2024, we report the resource use in daily operations, quantifying the total weight of technical and biological materials. In 2024, 45% of biological materials were sourced with a certification, indicating compliance with recognized sustainability standards. Additionally, 73% of all materials consisted of recycled components. These figures provide insight into our material use and the extent to which sustainable sourcing practices are applied in procurement.

By increasing the share of recycled materials, we aim to reduce reliance on newly sourced materials and improve resource efficiency. Monitoring resource inflows contributes to greater transparency and supports informed decision-making regarding material consumption. While there is room for improvement in the share of certified biological materials, this reporting provides a baseline for evaluating progress in future reporting cycles. These efforts align with circular economy principles and contribute to our broader sustainability objectives.

This represents a new metric introduced as part of the 2024 implementation of the CSRD. As such, no comparative data from previous periods is available.

Resource outflows

Actions

PostNL recognise the environmental impact of our packaging solutions for customers and the disposal of returned goods at their request. To address this, we have defined actions to mitigate these impacts and associated risks. Additionally, we see significant opportunities in adopting circular principles within our value chain to drive sustainable practices and reduce environmental impact.

Enable circular business models

We are focused on creating propositions that enable circularity, particularly in areas such as re-commerce, smart logistics for e-waste, reusable packaging, textiles, and repairs. We are actively engaging with our customers and trade organisations to develop scalable solutions that can accelerate this transition.

While this action plan is still under development, we have already taken a number of steps towards our goals. Key initiatives include:

- Introducing re-commerce solutions and services for the collection of e-waste and textiles, enabling the reuse and recycling of valuable materials.

- Actively participating in, and taking a leadership role within, the Circular Shopping 2030 programme, an initiative spearheaded by Thuiswinkel.org, aimed at fostering sustainable and circular retail practices.

- Introducing shipping and return label to reduce packaging and labels.

Circular Shopping 2030 programme

As founding partner and sponsor of The Circular Shopping 2030 programme, an initiative by thuiswinkel.org, we aim to support consumers in transitioning from a consumption-focused mindset to a usage-based approach by 2030, ensuring products and materials retain their value for significantly longer. In 2024, we continued to refine and actively contribute to the programme’s vision, collaborating with industry stakeholders to drive its progress. As part of these efforts, in 2023 we co-developed the Circular Flywheel. This strategic tool empowers businesses to assess their current position in circularity, identify opportunities for improvement, and set clear aspirations for the future.

Right to Repair

Our focus in 2024 also extended to the Right to Repair initiative, which is a new consumer right adopted by the European Union, aimed at making it easier and more attractive for consumers to have their goods repaired both within and beyond the legal guaranteed term. This is a significant trend influencing the e-commerce sector, and we engaged with partners to address its implications and opportunities.

We aim to enhance collaboration across the value chain, recognising the EU’s ambition to achieve 50% circularity by 2030. To meet evolving demands, both consumers and producers must adopt circular principles. We believe we are well-positioned to lead in this transition, offering reverse logistics solutions that support circular business models. Our efforts focus on customers and beyond, with medium- and long-term actions integrated into our strategy. While this approach is under development, several propositions, such as those outlined above, are already in place, reflecting our commitment to driving the circular economy forward.

Reduce residual waste

Our ambition is to develop a roadmap to further decrease our residual waste. We are committed to managing our waste streams as effectively as possible, and we are now working closely with our waste partners to achieve this. Together, we have undertaken comprehensive waste scans to analyse our waste processing and identify opportunities to improve waste separation, ultimately contributing to a reduction in carbon emissions. By reducing residual waste, we can reduce our CO2 emissions in scope 3.

Key actions

- New collection points; We complement new collection points by clear and efficient waste sorting instructions, designed to facilitate effective waste separation practices on all our locations.

- Promoting waste separation: Whenever we implement significant changes to our waste collection processes, we engage our employees with an informative kick-off event at the location. Additionally, we appoint waste ambassadors to raise awareness and emphasise the importance of proper waste separation. Clear labelling on waste containers helps simplify the process for employees.

- Continuous monitoring and evaluation: We have installed a waste management dashboard and regularly monitor the effectiveness of waste separation practices at our locations. Process managers oversee the separation process and discuss the results during location work meetings. On a quarterly basis, we review performance together and determine if any adjustments are needed to improve the process or employee behaviour.

In 2023, our residual waste averaged 38%. By the end of 2024, we had already reduced this to 27% through better waste separation. All our actions listed above focus on our operations and downstream value chain. These actions have an ongoing time horizon with no specific end date.

Targets

Our primary target is to achieve a 90% reduction in residual waste compared to 2022 in 2040, aligned with our science-based targets. Since our waste is directly linked to our operations, you can find more detailed information on this target in the section resource inflows.

Metrics

Resource outflows, including waste

PostNL acknowledges that, as a logistics provider rather than a production company, the metrics under resource outflows are not material to our operations. Specifically, we do not report on 'production and materials' metrics, as these are designed for manufacturing processes that are not applicable to PostNL’s business model. However, we do recognise the environmental impact of our packaging solutions for customers and the destruction of returned goods at their request. Refer to the actions described earlier in this section how we address these impacts and mitigate the associated risks.

Waste management

PostNL’s waste reduction and management strategy focuses on minimising waste across all stages of our operations, from sorting centres to final delivery. We have partnered with waste management companies in the Netherlands and Belgium, who provide data on waste streams and help us improve recycling efforts.

Waste composition

The waste generated by PostNL is composed of hazardous and non-hazardous waste, and in line with the key waste streams relevant to the logistics sector, mainly operational waste and packaging waste.

Hazardous waste

Includes batteries (lithium and lead-acid), used oils, fire extinguishers, toners and small hazardous waste (KGA). These streams are safely handled and processed by certified partners to ensure compliance with environmental regulations.

PostNL does not generate radioactive waste as defined under Article 3(7) of Council Directive 2011/70/Euratom. However, hazardous waste streams are generated as part of our operations and are managed to ensure compliance with safety and environmental regulations.

Non-hazardous waste

- Operational waste: Includes wood, old iron (scrap metal), organic waste (fermentation in pallet boxes or pallets), film (plastic).

- E-waste: Obsolete electronic devices such as monitors and white goods.

- Packaging waste: Cardboard, PMD (plastic, metal, drink cartons), and other recyclable packaging materials.

- General office waste: Paper, confidential document boxes, and other consumables.

This broad waste composition reflects the diversity of PostNL's operational processes, and the variety of materials handled throughout its logistics operations. Through our partnerships with waste management companies, we continue to optimise the management and recycling of these waste streams, ensuring we meet our sustainability targets. Some of the waste comes from shipments that cannot be delivered, for example because they break in the process between the sender and recipient. PostNL, as a service provider specialising in logistics, generates waste streams primarily related to the collection, sorting, and delivery of goods.

Assumptions, limitations and goals

The definitions applied are in line with the ESRS requirements, for example our recycling excludes operations like biomass energy recovery. Furthermore, the classification of recovery and disposal operations excludes biomass recovery from recycling and categorises it under ‘other recovery operations’.

The waste data disclosed is primarily sourced from our waste management partner in the Netherlands. This waste dashboard covers approximately 95% of our operations in the Netherlands. For areas not covered, the waste data is scaled proportionally to provide a comprehensive view across all operations. To address this, we plan to expand the scope of waste data collection to include Belgium by 2025. Refer to the Data extrapolation sustainability statement in the Appendices for information regarding extrapolation of lacking or missing data.

We have set ambitious goals, including reducing packaging use by 15% by 2040 compared to 2018, as part of our ongoing commitment to sustainability. Through partnerships with suppliers, we also ensure that pre-consumer waste, such as packaging materials, is managed efficiently. While we do not produce packaging materials ourselves, we continuously promote eco-friendly packaging options and circular solutions to our customers, contributing to overall waste reduction.

PostNL Recycled waste as indicated

2023 - 2024

| Year ended at 31 December | 2023 | 2024 |

|---|---|---|

| Total amount of non-recycled waste (tonnes) | 1,697 | 1,704 |

| Total amount of recycled waste (tonnes) | 2,747 | 4,698 |

| Total amount of waste generated (tonnes) | 4,444 | 6,402 |

| Non-recycled waste as share of total waste (%) | 38% | 27% |

| Recycled waste as share of total waste (%) | 62% | 73% |

In 2024, 73% of PostNL’s total waste was recycled, an improvement from 62% in 2023, while non-recycled waste decreased to 27%. The majority of waste was diverted from disposal through recycling and recovery operations. These results reflect PostNL’s progress in optimizing waste separation, increasing recycling rates, and reducing residual waste across logistics operations. Throughout the year we focused on informing our employees at sorting centers about the importance of recycling. In addition, we made recycling easier for our employees at parcel sorting centers, by placing recycling bins and carton presses closer to the sorting processes that generate waste. The total amount of generated waste increased compared to 2023, because of an increase in parcel volumes.

PostNL Waste per recovery operation and treatment type

in tonnes

2023 - 2024

| Year ended at 31 December | 2023 | 2024 |

|---|---|---|

| Total amount by weight diverted from disposal | 4,444 | 6,402 |

| Hazardous waste | 36 | 44 |

| Preparation for reuse | 0 | 0 |

| Recycling | 3 | 4 |

| Other recovery operations | 33 | 40 |

| Non-hazardous waste | 4,408 | 6,358 |

| Preparation for reuse | 0 | 0 |

| Recycling | 2,744 | 4,694 |

| Other recovery operations | 1,664 | 1,664 |

| Total amount by weight directed to disposal | 0 | 0 |

| Hazardous waste | 0 | 0 |

| Incineration | 0 | 0 |

| Landfill | 0 | 0 |

| Other disposal operations | 0 | 0 |

| Non-hazardous waste | 0 | 0 |

| Incineration | 0 | 0 |

| Landfill | 0 | 0 |

| Other disposal operations | 0 | 0 |

| Total amount of waste generated | 4,444 | 6,402 |

The total amount of waste generated increased compared to 2023. While total waste volumes were higher, the amount of waste directed to disposal decreased, reflecting adjustments in waste management practices. The increase in recycling volumes was influenced by improved waste separation processes and higher recovery rates for non-hazardous materials. Hazardous waste remained a small fraction of the total waste stream and was managed in compliance with applicable regulations. These results provide insight into PostNL’s waste management approach, with a focus on enhancing data accuracy, improving waste separation, and optimizing resource recovery in line with circular economy principles.